A-K Series™ Knurled Threaded Insert

The A-K Series™ is identical to the A-L Series™ but features a low profile head for applications requiring near flush mating part assembly.

The A-K Series™ Knurled Threaded Insert features a knurled body and a reduced profile head to allow for virtually flush installation. Countersink drilling or dimpling of the parent material can be eliminated. The A-K Insert is designed to be used with Grade 5 or Metric Class 8.8/9.8 mating screws.

The A-K Insert can be installed using AVK’s ARO brand Pneumatic Tools or AVK’s SPP™ Pneumatic/Hydraulic Tools. These tools can be located at any position on your assembly line. The A-K Insert can be installed either before or after finish.

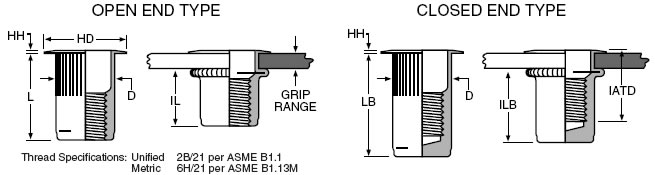

Open End

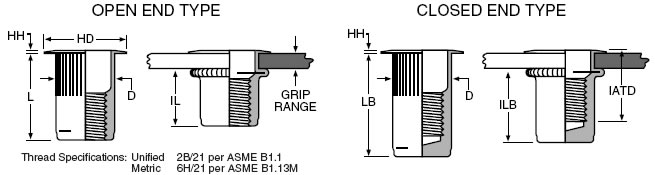

Closed End

Thread area is enclosed eliminating leakage past the threads from either side of the application.

AKS3T-420-165

| AK | ( ) | ( ) | - ( ) | - ( ) | ( ) | |||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

* Special order items are subject to minimum order requirements. Contact AVK for details.

THE A-K SERIES™ INSERT - THREAD SIZES

UNIFIED(INCH) SIZES |

||||||||||||

| Thread Size | Thread Call Out | Grip Range | Grip Call Out | Hole Size +.006 -.000 | HD ±.010 ±0.25* | HH ±.003 | L ±.015 | D Max. | IL Max. | LB ±.015 | ILB Max | IATD* Max. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6-32 UNC | 632 | .020-.080 | 80 | 17/64 (.2656) | .310 | .019 | .420 | .265 | .305 | .740 | .640 | .610 |

| 6-32 UNC | 632 | .080-.130 | 130 | 17/64 (.2656) | .310 | .019 | .470 | .265 | .305 | .740 | .580 | .670 |

| 8-32 UNC | 832 | .020-.080 | 80 | 17/64 (.2656) | .310 | .019 | .420 | .265 | .305 | .740 | .640 | .610 |

| 8-32 UNC | 832 | .080-.130 | 130 | 17/64 (.2656) | .310 | .019 | .470 | .265 | .305 | .740 | .580 | .670 |

| 10-24 UNC | 1024 | .020-.130 | 130 | 19/64 (.2969) | .340 | .019 | .475 | .296 | .315 | .990 | .845 | .730 |

| 10-24 UNC | 1024 | .130-.225 | 225 | 19/64 (.2969) | .340 | .019 | .585 | .296 | .315 | .990 | .735 | .840 |

| 10-32 UNF | 1032 | .020-.130 | 130 | 19/64 (.2969) | .340 | .019 | .475 | .296 | .315 | .990 | .845 | .730 |

| 10-32 UNF | 1032 | .130-.225 | 225 | 19/64 (.2969) | .340 | .019 | .585 | .296 | .315 | .990 | .735 | .840 |

| 1/4-20 UNC | 420 | .027-.165 | 165 | 25/64 (.3906) | .455 | .022 | .580 | .390 | .380 | 1.190 | 1.005 | .895 |

| 1/4-20 UNC | 420 | .165-.260 | 260 | 25/64 (.3906) | .455 | .022 | .680 | .390 | .380 | 1.190 | .905 | 1.035 |

| 5/16-18 UNC | 518 | .027-.150 | 150 | 17/32 (.5312) | .595 | .022 | .690 | .530 | .470 | 1.390 | 1.175 | .995 |

| 5/16-18 UNC | 518 | .150-.312 | 312 | 17/32 (.5312) | .595 | .022 | .805 | .530 | .425 | 1.390 | 1.025 | 1.120 |

| 3/8-16 UNC | 616 | .027-.150 | 150 | 17/32 (.5312) | .595 | .022 | .690 | .530 | .470 | 1.390 | 1.175 | .995 |

| 3/8-16 UNC | 616 | .150-.312 | 312 | 17/32 (.5312) | .595 | .022 | .805 | .530 | .425 | 1.390 | 1.025 | 1.120 |

METRIC SIZES

| Thread Size | Thread Call Out | Grip Range | Grip Call Out | Hole Size +0,15 -0,00 | HD ±0,25 ±0,64* | HH ±0,08 | L ±0,38 | D Max. | IL Max. | LB ±0,38 | ILB Max | IATD* Max. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M4 x 0,7 ISO | 470 | 0,50-2,00 | 2.0 | 6,75 | 7,87 | 0,48 | 10,67 | 6,73 | 7,75 | 18,80 | 16,26 | 15,49 |

| M4 x 0,7 ISO | 470 | 2,00-3,30 | 3.3 | 6,75 | 7,87 | 0,48 | 11,94 | 6,73 | 7,75 | 18,80 | 14,73 | 17,02 |

| M5 x 0,8 ISO | 580 | 0,50-3,30 | 3.3 | 7,60 | 8,64 | 0,48 | 12,07 | 7,52 | 8,00 | 25,15 | 21,46 | 18,54 |

| M5 x 0,8 ISO | 580 | 3,30-5,70 | 5.7 | 7,60 | 8,64 | 0,48 | 14,86 | 7,52 | 8,00 | 25,15 | 18,67 | 21,34 |

| M6 x 1,0 ISO | 610 | 0,70-4,20 | 4.2 | 10,00 | 11,56 | 0,55 | 14,73 | 9,91 | 9,65 | 30,23 | 25,53 | 22,73 |

| M6 x 1,0 ISO | 610 | 4,20-6,60 | 6.6 | 10,00 | 11,56 | 0,55 | 17,27 | 9,91 | 9,65 | 30,23 | 22,99 | 26,29 |

| M8 x 1,25 ISO | 8125 | 0,70-3,80 | 3.8 | 13,50 | 15,11 | 0,55 | 17,53 | 13,46 | 11,94 | 35,31 | 29,85 | 25,27 |

| M8 x 1,25 ISO | 8125 | 3,80-7,90 | 7.9 | 13,50 | 15,11 | 0,55 | 20,45 | 13,46 | 10,80 | 35,31 | 26,04 | 28,45 |

| M10 x 1,5 ISO | 1015 | 0,70-3,80 | 3.8 | 13,50 | 15,11 | 0,55 | 17,53 | 13,46 | 11,94 | 35,31 | 29,85 | 25,27 |

| M10 x 1,5 ISO | 1015 | 3,80-7,90 | 7.9 | 13,50 | 15,11 | 0,55 | 20,45 | 13,46 | 10,80 | 35,31 | 26,04 | 28,45 |

- NOTE 1: Grip range can be affected by parent material density and actual hole size. AVK suggests trial installations to determine optimum grip.

- NOTE 2: Additional UNF fine threads are available. Contact AVK for details.

- NOTE 3: Additional grip lengths are available in certain thread sizes. Contact AVK for details.

- *Dimensions in minimum grip condition.