A-R Series™ Threaded Insert

A-R Series™ Threaded Insert has been designed for use in plastics and thin gauge sheet metal applications where increased pull-out resistance is required.

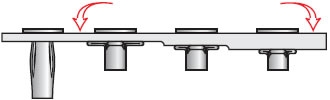

The A-R Insert features a PreSet™ slotted body design that when installed folds into four segments gripping the backside of the parent material. This design feature allows the A-R Insert to be installed into single, variable or multiple thickness materials using AVK’s ARO torque-stall Pneumatic Tools or AVK’s SPP™ Pneumatic/Hydraulic Tools.

A-R SERIES™ PRESET™ DESIGN

HOW IT WORKS FOR YOU

The Preset™ slightly expanded slotted body design of the A-R Series™ enables it to be installed using torque type tools.

Hand or pneumatic torque tools will install the A-R Series™ in single, variable or multiple thickness materials.

A-R Studs

An A-R blind side, petaled footprint produces exceptional pull-out combined with a stud for component attachment.

Special Head Designs

Special head configurations such as square or wedge head can increase the inserts holding resistance in the parent material.

Straight Body Design

A straight body A-R Series™ insert is ideal for thin sheet metals, tubing & plastic applications where high pull-out is required.

Step 1

The operator 1/4 turns the AVK fastener on to the tool mandrel and places it into the hole. Operator then presses the top trigger on the tool and the AVK part installs.

Step 2

Once hole fill is complete, the AVK fastener forms its backside flange behind the parent material and the tool stalls.

Step 3

The operator reverses the tool and proceeds to attach the mating component using the appropriate mating hardware. The entire installation sequence of the AVK fastener takes 3 seconds or less.

Notes:

The operator can install the AVK fastener into two different material thickness’. This is the key benefit of the AVK System. You are able to install our products into single, variable or multiple thickness materials without tool adjustment.

During installation the AVK fastener expands within the hole Filling The Hole. This assures excellent spin out resistance and is a feature unique to AVK fasteners.

AVK fasteners are designed to be installed right on your assembly line either before or after paint or finish is applied to your product. This saves space and improves process flow.

ARS3T-420-165

| AR | ( ) | ( ) | - ( ) | - ( ) | |||||||||||||||

|

|

||||||||||||||||||

|

|

|

|

|

* Special order items are subject to minimum order requirements. Contact AVK for details.

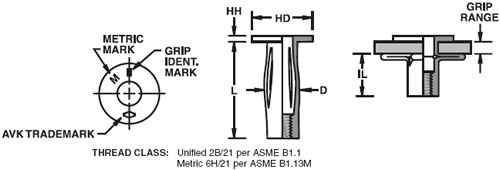

THE A-R SERIES™ INSERT - THREAD SIZES

Unified (Inch) and Metric Thread Sizes |

|||||||||||||

| Thread Size | Thread Call Out | Grip Range | Grip Call Out | Hole Size | HD | HH | L | D | IL Max. | Grip ID Mark | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4-20 UNC | 420 | .020-.280 | 280 | .390 .396 |

.645 .610 |

.063 .053 |

1.015 .985 |

.382 .368 |

.520 | Blank | |||

| 1/4-20 UNC | 420 | .280-.500 | 500 | .390 .396 |

.645 .610 |

.063 .053 |

1.249 1.219 |

.382 .368 |

.520 | 1 Rad | |||

| 5/16-18 UNC | 518 | .020-.280 | 280 | .500 .506 |

.770 .740 |

.067 .057 |

1.156 1.126 |

.495 .490 |

.775 | Blank | |||

| 5/16-18 UNC | 518 | .280-.500 | 500 | .500 .506 |

.770 .740 |

.067 .057 |

1.390 1.360 |

.495 .490 |

.775 | 1 Rad | |||

| 3/8-16 UNC | 616 | .020-.280 | 280 | .594 .600 |

.865 .895 |

.083 .093 |

1.205 1.233 |

.582 .587 |

.775 | Blank | |||

| M6x1,0 ISO | 610 | 0,5-7,1 | 7.1 | 10,00 10,15 |

16,38 15,49 |

1,60 1,35 |

25,78 25,02 |

9,8 9,35 |

13,21 | Blank | |||

| M6x1,0 ISO | 610 | 7,1-12,7 | 12.7 | 10,00 10,15 |

16,38 15,49 |

1,60 1,35 |

31,72 30,96 |

9,8 9,35 |

13,21 | 1 Rad | |||

| M8x1,25 ISO | 8125 | 0,5-7,1 | 7.1 | 12,70 12,85 |

19,56 18,80 |

1,70 1,45 |

29,63 28.60 |

12,57 12,47 |

19,69 | Blank | |||

| M8x1,25 ISO | 8125 | 7,1-12,7 | 12.7 | 12,70 12,85 |

19,56 18,80 |

1,70 1,45 |

35,31 34.54 |

12,57 12,47 |

19,69 | 1 Rad | |||

| M10x1,5 ISO | 1015 | 0,5-7,1 | 7.1 | 15,09 15,24 |

22,73 21,97 |

2,36 2,11 |

31,32 30.61 |

14,91 14,78 |

19,69 | Blank | |||

- NOTE 1: Grip range stated in the dimensional chart above can be achieved using pull type installation tools and may be variable based on hole size and parent material density. AVK recommends trial installations to determine actual grip range in the application.

- NOTE 2: Grip ranges will be less than stated above when using torque type installation tools. Grip range will be affected by the tool RPM speed, stall torque, hole size and parent material density. AVK recommends trial installations to determine actual grip. See page 33 for torque tool selection guidelines.