R-N Series® RivetNut Insert

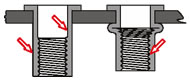

R-N Series® RivetNut Threaded Insert features a heavy duty head profile and increased wall thickness in the collapse area. This makes the R-N RivetNut ideal for leg leveling.

R-N Series® RivetNut Threaded Insert can be installed using AVK’s SPP™ Pneumatic/Hydraulic Tools. The R-N Insert’s heavier wall thickness and resulting upset load requires this type of tool be used for installation. The R-N Insert can be installed either prior to or after finish.

COLD FORMING TECHNOLOGY™

HOW IT WORKS FOR YOU

The R-N Series® Rivet Nuts are manufactured using state-of-the-art cold forming technology. This provides very precise tolerances. All surfaces of the R-N Series® are FORMED, not machined. This provides excellent quality.

The internal thread of the R-N Series® Rivet Nut is roll FORMED not machined. This provides excellent thread strength.

Closed End

Thread area is enclosed eliminating leakage past the threads from either side of the application.

Keyed Head

An underside of the head “key” projection when placed into a matching “keyed” hole design provides additional torque resistance.

100° COUNTERSUNK HEAD

A 100° countersunk head profile when installed into a matching countersunk hole provides a flush installation.

Contact AVK for availability.

RNS3T-420-80

| RN | ( ) | ( ) | - ( ) | - ( ) | ( ) | |||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

* Special order items are subject to minimum order requirements. Contact AVK for details.

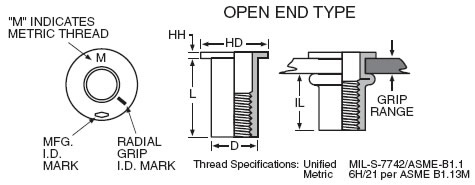

THE R-N SERIES® RIVETNUT INSERT - THREAD SIZES

UNIFIED(INCH) SIZES

| Thread Size |

Thread Call Out |

Grip Range |

Grip Call Out |

I.D. Mark |

Hole Size +.003 -.000 |

HD ±.015 |

HH Nom. |

L ±.015 |

D +.000 -.004 |

IL Ref. |

| 4-40 UNC | 440 | .010-.060 | 60 | blank | 5/32 (.155) | .270 | .025 | .345/td> | .155 | .230 |

| 4-40 UNC | 440 | .060-.085 | 85 | 1-Rad | 5/32 (.155) | .270 | .025 | .370 | .155 | .230 |

| 4-40 UNC | 440 | .085-.110 | 110 | 2-Rad | 5/32 (.155) | .270 | .025 | .400 | .155 | .230 |

| 6-32 UNC | 632 | .010-.075 | 75 | 1-Rad | #12 (.189) | .325 | .032 | .438 | .189 | .300 |

| 6-32 UNC | 632 | .075-.120 | 120 | 3-Rad | #12 (.189) | .325 | .032 | .500 | .189 | .315 |

| 6-32 UNC | 632 | .120-.160 | 160 | 5-Rad | #12 (.189) | .325 | .032 | .500 | .189 | .270 |

| 8-32 UNC | 832 | .010-.075 | 75 | 1-Rad | #2 (.221) | .357 | .032 | .438 | .221 | .300 |

| 8-32 UNC | 832 | .075-.120 | 120 | 3-Rad | #2 (.221) | .357 | .032 | .500 | .221 | .315 |

| 8-32 UNC | 832 | .120-.160 | 160 | 5-Rad | #2 (.221) | .357 | .032 | .500 | .221 | .270 |

| 10-32 UNF | 1032 | .010-.080 | 80 | blank | 1/4 (.250) | .406 | .038 | .531 | .250 | .380 |

| 10-32 UNF | 1032 | .080-.130 | 130 | 1-Rad | 1/4 (.250) | .406 | .038 | .594 | .250 | .390 |

| 10-32 UNF | 1032 | .130-.180 | 180 | 2-Rad | 1/4 (.250) | .406 | .038 | .641 | .250 | .390 |

| 1/4-20 UNC | 420 | .020-.080 | 80 | blank | Q (.332) | .475 | .058 | .625 | .332 | .450 |

| 1/4-20 UNC | 420 | .080-.140 | 140 | 1-Rad | Q (.332) | .475 | .058 | .687 | .332 | .450 |

| 1/4-20 UNC | 420 | .140-.200 | 200 | 2-Rad | Q (.332) | .475 | .058 | .750 | .332 | .450 |

| 5/16-18 UNC | 518 | .030-.125 | 125 | blank | Z (.413) | .665 | .062 | .750 | .413 | .505 |

| 5/16-18 UNC | 518 | .125-.200 | 200 | 1-Rad | Z (.413) | .665 | .062 | .875 | .413 | .555 |

| 5/16-18 UNC | 518 | .200-.275 | 275 | 2-Rad | Z (.413) | .665 | .062 | .937 | .413 | .540 |

| 3/8-16 UNC | 616 | .030-.115 | 115 | blank | 12,5 mm (.490) | .781 | .088 | .844 | .490 | .585 |

| 3/8-16 UNC | 616 | .115-.200 | 200 | 1-Rad | 12,5 mm (.490) | .781 | .088 | .938 | .490 | .595 |

| 3/8-16 UNC | 616 | .200-.285 | 285 | 2-Rad | 12,5 mm (.490) | .781 | .088 | 1.031 | .490 | .605 |

| 1/2-13 UNC | 813 | .050-.150 | 150 | blank | 5/8 (.625) | .906 | .085 | .906 | .625 | .605 |

| 1/2-13 UNC | 813 | .150-.250 | 250 | 1-Rad | 5/8 (.625) | .906 | .085 | 1.031 | .625 | .630 |

| 1/2-13 UNC | 813 | .250-.350 | 350 | 2-Rad | 5/8 (.625) | .906 | .085 | 1.141 | .625 | .640 |

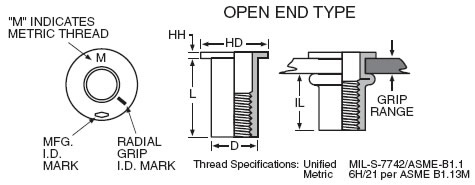

METRIC SIZES

| Thread Size |

Thread Call Out |

Grip Range |

Grip Call Out |

I.D. Mark |

Hole Size +0,08 -0,00 |

HD ±0,38 |

HH Nom. |

L ±0,38 |

D +0,00 -0,10 |

IL Ref. |

| M3x0,5 ISO | 350 | 0,25-1,00 | 1.0 | blank | 3,94 | 6,68 | 0,63 | 8,00 | 3,93 | 5,61 |

| M3x0,5 ISO | 350 | 1,00-1,75 | 1.75 | 1-Rad | 3,94 | 6,68 | 0,63 | 8,75 | 3,93 | 5,61 |

| M3x0,5 ISO | 350 | 1,75-2,50 | 2.5 | 2-Rad | 3,94 | 6,68 | 0,63 | 9,50 | 3,93 | 5,61 |

| M4x0,7 ISO | 470 | 0,25-2,00 | 2.0 | blank | 5,60 | 9,01 | 0,81 | 11,00 | 5,61 | 7,08 |

| M4x0,7 ISO | 470 | 2,00-3,00 | 3.0 | 1-Rad | 5,60 | 9,01 | 0,81 | 12,00 | 5,61 | 7,08 |

| M4x0,7 ISO | 470 | 3,00-4,00 | 4.0 | 2-Rad | 5,60 | 9,01 | 0,81 | 13,00 | 5,61 | 7,08 |

| M5x0,8 ISO | 580 | 0,25-2,00 | 2.0 | blank | 7,20 | 11,17 | 1,22 | 14,50 | 7,13 | 10,09 |

| M5x0,8 ISO | 580 | 2,00-3,50 | 3.5 | 1-Rad | 7,20 | 11,17 | 1,22 | 16,00 | 7,13 | 10,09 |

| M5x0,8 ISO | 580 | 3,50-5,00 | 5.0 | 2-Rad | 7,20 | 11,17 | 1,22 | 17,50 | 7,13 | 10,09 |

| M6x1,0 ISO | 610 | 0,75-2,00 | 2.0 | blank | 8,50 | 13,43 | 1,47 | 15,50 | 8,43 | 10,58 |

| M6x1,0 ISO | 610 | 2,00-3,50 | 3.5 | 1-Rad | 8,50 | 13,43 | 1,47 | 17,00 | 8,43 | 10,58 |

| M6x1,0 ISO | 610 | 3,50-5,00 | 5.0 | 2-Rad | 8,50 | 13,43 | 1,47 | 18,50 | 8,43 | 10,58 |

| M8x1,25 ISO | 8125 | 1,00-3,00 | 3.0 | blank | 10,50 | 16,65 | 1,57 | 18,00 | 10,48 | 11,83 |

| M8x1,25 ISO | 8125 | 3,00-5,00 | 5.0 | 1-Rad | 10,50 | 16,65 | 1,57 | 20,00 | 10,48 | 11,83 |

| M8x1,25 ISO | 8125 | 5,00-7,00 | 7.0 | 2-Rad | 10,50 | 16,65 | 1,57 | 22,00 | 10,48 | 11,83 |

| M10x1,5 ISO | 1015 | 1,00-3,00 | 3.0 | blank | 12,50 | 19,50 | 2,23 | 20,00 | 12,44 | 13,20 |

| M10x1,5 ISO | 1015 | 3,00-5,50 | 5.5 | 1-Rad | 12,50 | 19,50 | 2,23 | 22,50 | 12,44 | 13,20 |

| M10x1,5 ISO | 1015 | 5,50-8,00 | 8.0 | 2-Rad | 12,50 | 19,50 | 2,23 | 25,00 | 12,44 | 13,20 |

| M12x1,75 ISO | 12175 | 1,00-3,00 | 3.0 | blank | 15,50 | 22,79 | 2,23 | 24,00 | 15,46 | 16,45 |

| M12x1,75 ISO | 12175 | 3,00-5,50 | 5.5 | 1-Rad | 15,50 | 22,79 | 2,23 | 26,50 | 15,46 | 16,45 |

| M12x1,75 ISO | 12175 | 5,50-8,00 | 8.0 | 2-Rad | 15,50 | 22,79 | 2,23 | 29,00 | 15,46 | 16,45 |

- NOTE 1: Grip range can be affected by parent material density and actual hole size. AVK suggests trial installations to determine optimum grip.

- NOTE 2: Additional UNF and UNC threads are available. Contact AVK for details.

- NOTE 3: RN Series threads are not gaugeable after installation.

- NOTE 4: Additional grip sizes, materials, head styles and closed end versions are available by special order. Contact AVK for details.